Energy-related operational Optimization

Save energy costs sustainably.

In detail

Energy-efficient operational optimization can reduce energy costs immediately and cost-effectively. At the same time, user comfort is improved and maintenance is reduced. Integrated coaching from the technical service team ensures the lasting impact of the measure.

Often, the settings of building services systems are no longer monitored or adjusted after commissioning. Changing user requirements or increased comfort expectations often result in new operating conditions. Energy-related operational optimization (eBO) quickly and cost-effectively adapts the control parameters of building services systems to new user requirements, saving energy and operating costs. Experience shows that the payback period for an eBO is between two and three years.

At the beginning of an eBO, SADRIJAJ, in collaboration with the operator's technical staff, documents the current status of the building services systems and defines the current user requirements. This is followed by the development and discussion of possible optimization measures for the individual building services systems.

Possible optimization measures are then implemented jointly during several on-site coaching sessions. The coaching also serves to train and sensitize the technical staff on the topics of eBO and energy efficiency. This enables them to respond independently to user changes in the future with energy-efficient settings.

This approach serves to gradually move toward sustainably efficient and thus cost-reduced plant operation while simultaneously increasing user comfort. As a positive side effect, optimized plant operation reduces the number of malfunctions.

Determination of current status

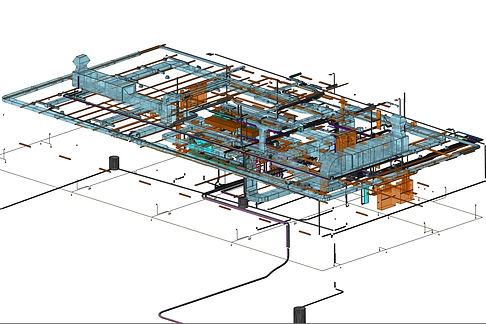

The recording of the system parameters and the operator's experience is carried out on-site with the technical service. This includes not only the technical parameters of the systems, but also the operating requirements and experience of the company. We compile the recordings clearly and present them graphically.

Optimization of the systems

Based on the data collected, we will prepare an optimization proposal for you. The optimization proposals for the heating, ventilation, air conditioning, and refrigeration systems will be discussed with the technical department and implemented together. We will calculate and report the energy savings resulting from the optimizations.

Technical service training

To ensure the sustainable impact of the eBO, a customized workshop will be conducted with the technical department. The significance of the setting parameters and operating times of the heating, ventilation, air conditioning, and refrigeration systems, as well as the function of the individual components and the overall system, will be discussed and explained in a workshop with the technical department.

Coaching

Coaching supports the technical department in the sustainable implementation of optimizations. The first coaching session will be held approximately one month after the optimizations have been implemented to reflect initial experiences. A further coaching session can be scheduled after one year to support your technical department in making adjustments.

Services

Structured documentation of system parameters & usage zones

Documentation of optimized parameters & calculated energy savings

eBO for heating, ventilation, air conditioning and refrigeration systems

Raising awareness among technical services